Understanding Prototype PCB Assembly Services

Definition and Importance

Prototype PCB assembly services refer to the specialized process of fabricating and assembling printed circuit boards (PCBs) for low-volume production runs, particularly for testing new designs before mass production. This stage is crucial for engineers and product developers, allowing them to validate their electronic design and functionalities. Efficient prototype PCB assembly services can significantly shorten the product development cycle, minimize costly errors in later stages, and accelerate time-to-market for new innovations.

Being able to iterate quickly on designs means that products can be improved based on real-world testing and feedback. Such responsiveness is essential in today’s fast-paced technology landscape, where advances occur rapidly and customer demands evolve swiftly. Utilizing prototype pcb assembly services can help manufacturers stay ahead of trends while maintaining efficiency and quality.

Applications in Various Industries

Prototype PCB assembly services are widely applied across multiple sectors, each benefiting from the precision and flexibility offered by these services. Key industries include:

- Consumer Electronics: Developers in this sector frequently utilize prototype assembly to test new devices, from smartphones to smart home technology, ensuring user satisfaction through rapid iteration.

- Automotive: As automotive technologies become increasingly reliant on electronics, prototype PCBs are crucial for developing prototypes of safety features, infotainment systems, and electric vehicles.

- Medical Devices: In the healthcare industry, precision is paramount. Prototype PCB assembly services facilitate the creation of prototypes for medical devices that require extensive testing to meet rigorous standards.

- Telecommunications: Telecom manufacturers leverage prototype assembly services to develop and test new equipment and infrastructure solutions, ensuring robust and efficient communication frameworks.

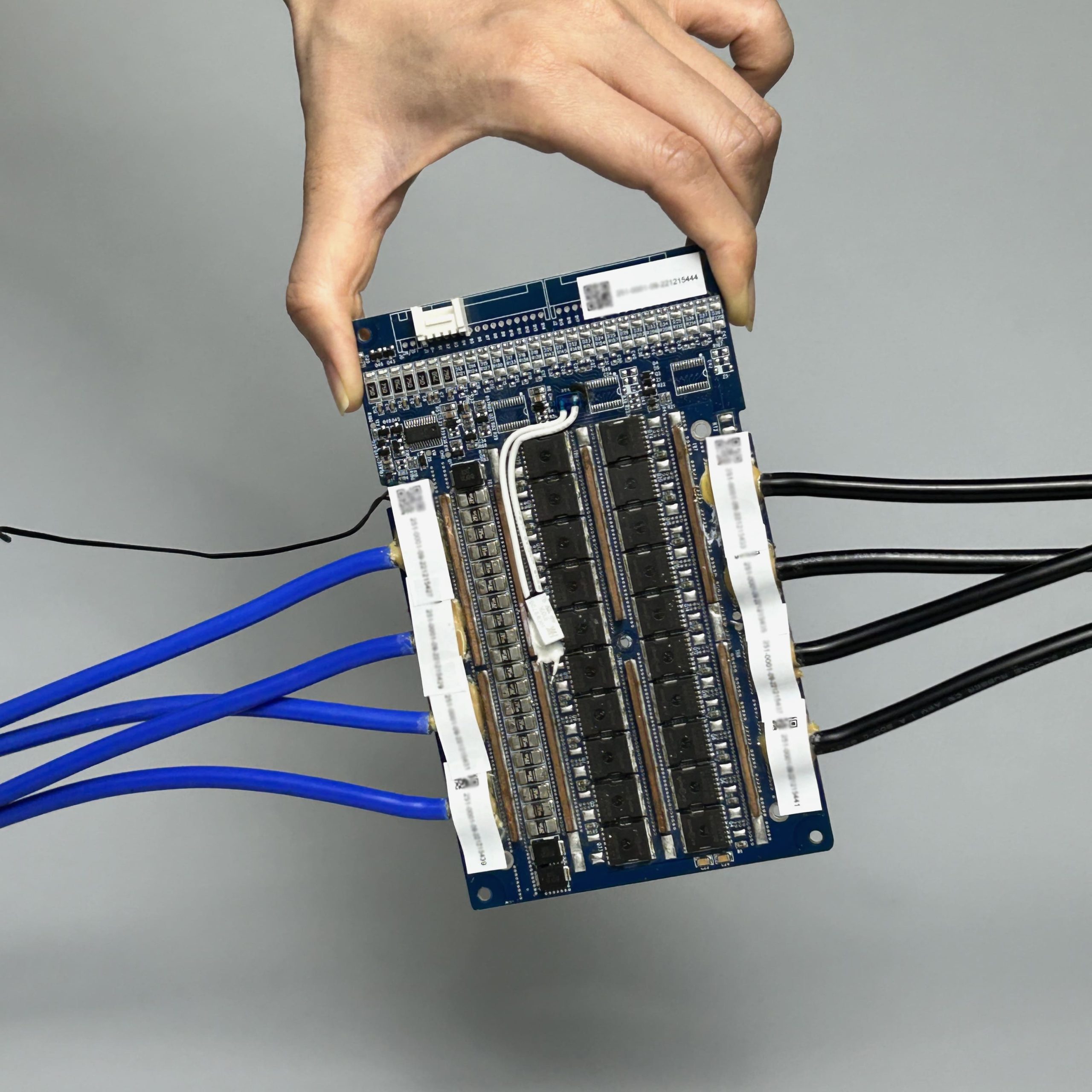

Key Components of PCB Assembly

Understanding the key components involved in prototype PCB assembly is essential for ensuring quality and functionality. These components typically include:

- Printed Circuit Board (PCB): The fundamental component where the circuit pathways are etched to connect various electronic parts.

- Electronic Components: Includes resistors, capacitors, diodes, and integrated circuits that perform specific functions within the circuit.

- Solder: Used to join electronic components to the PCB, ensuring stable connections and functionality.

- Assembly Processes: Methods such as surface mount technology (SMT) and through-hole assembly are employed to place components onto the PCB efficiently.

Stages of the Prototype PCB Assembly Process

Design and Prototyping

The initial phase of the PCB assembly process involves design conception, often utilizing computer-aided design (CAD) software to create schematics and layouts. This design must take into account various factors such as:

- Space Constraints: The physical layout must allow for effective component placement while preserving function.

- Signal Integrity: Ensuring proper signal strength and clarity throughout the circuit.

- Thermal Management: Proper placement and materials are critical to avoid overheating in operational environments.

Once the design is finalized, a prototype PCB is fabricated for testing. This prototype will undergo various assessments to verify correct functionality and identify any design flaws.

Sourcing Components Efficiently

Once the prototype design is ready, the next step involves sourcing components. Efficient sourcing is vital as it impacts the overall timeline and cost. Best practices for sourcing include:

- Establishing Relationships: Building strong relationships with suppliers can lead to better pricing and reliability.

- Inventory Management: Keeping track of inventory levels and lead times ensures that components are available when needed.

- Quality Assurance: Thoroughly vetting suppliers and using certified parts ensures the reliability and performance of the final product.

Assembly Techniques Explained

The assembly stage involves placing electronic components onto the PCB, which can be done using various techniques. The most common methods include:

- Surface Mount Technology (SMT): This is a widely used method where components are mounted directly onto the surface of the PCB. SMT provides several advantages, such as compact designs and automated assembly capabilities.

- Through-Hole Technology: Components are inserted through holes in the PCB and soldered from the opposite side. This technique is still valuable for larger components or where mechanical strength is required.

Each assembly method presents distinct advantages and should be chosen based on the specific requirements of the prototype being developed.

Choosing the Right Partner for PCB Assembly

Factors to Consider in Selection

Selecting the right partner for prototype PCB assembly can greatly affect the outcome of the project. Key factors to consider include:

- Experience and Expertise: An established provider with a proven track record can help in navigating complexities and ensuring a high-quality outcome.

- Production Capabilities: Understanding the manufacturer’s capacity to handle your specific requirements, including the number of prototypes needed and required turnaround times, is crucial.

- Technological Advancements: The use of modern technology in both design and assembly can enhance product reliability and streamline production processes.

Evaluating Quotes and Proposals

When sourcing PCB assembly services, evaluating quotes and proposals is key to ensuring value for money. Considerations include:

- Cost Transparency: A clear breakdown of costs that includes design, components, and assembly can help avoid hidden fees later on.

- Lead Time: Understanding the expected lead time is crucial; a lower cost solution may be less appealing if it significantly delays product launch.

- Flexibility and Support: The ability to make changes and receive support during the assembly process can significantly enhance project outcomes.

Assessing Quality Control Measures

Quality control is an essential component of any assembly process. Evaluate a service provider’s quality control measures to ensure reliable end products. Best practices include:

- Testing Protocols: Ask about in-circuit testing, functional testing, and visual inspection processes to understand how quality is assured.

- Certifications: Compliance with industry standards (like ISO) can be indicative of a commitment to quality.

- Feedback Mechanisms: A partner that encourages and implements feedback can lead to continuous improvements and better outcomes in subsequent projects.

Common Challenges in PCB Assembly

Addressing Supply Chain Issues

Supply chain disruptions can delay production timelines and escalate costs. To mitigate risks associated with these challenges:

- Diverse Sourcing Strategies: Engaging multiple suppliers can reduce dependency on a single source, spreading risk.

- Inventory Buffering: Maintaining a safety stock of critical components can prevent short-term disruptions from affecting production.

Mitigating Design Flaws

Design flaws are among the most common issues that occur during PCB assembly. Implementing thorough design reviews and validations can help catch potential issues before they escalate. Ensuring collaboration among design engineers, assembly teams, and quality control personnel can lead to identifying and rectifying potential flaws early in the process.

Managing Production Timelines

Balancing quality assurance with aggressive timelines can be challenging. Establishing clear communication channels throughout the project lifecycle allows for immediate identification and resolution of issues. Utilizing project management tools can facilitate tracking and accountability at each stage of the assembly process.

Best Practices for Prototype PCB Assembly Success

Implementing Design Reviews

Conducting design reviews at key milestones throughout the project ensures that potential issues are addressed early. This collaborative approach involves cross-functional teams, which can lead to more innovative solutions and effectively streamline the design iteration process.

Utilizing the Latest Technology

Adopting cutting-edge technology in toolbox and assembly processes enhances accuracy and speeds up production. Implementing automation in assembly lines may optimize both the speed and quality of outputs.

Ensuring Effective Communication with Teams

Open communication channels among project stakeholders can foster collaboration and reduce misunderstandings. Regular updates and feedback loops ensure that every team member is aligned and can help prevent potential setbacks in production.