Understanding Injection Molding Machines

What is an Injection Molding Machine?

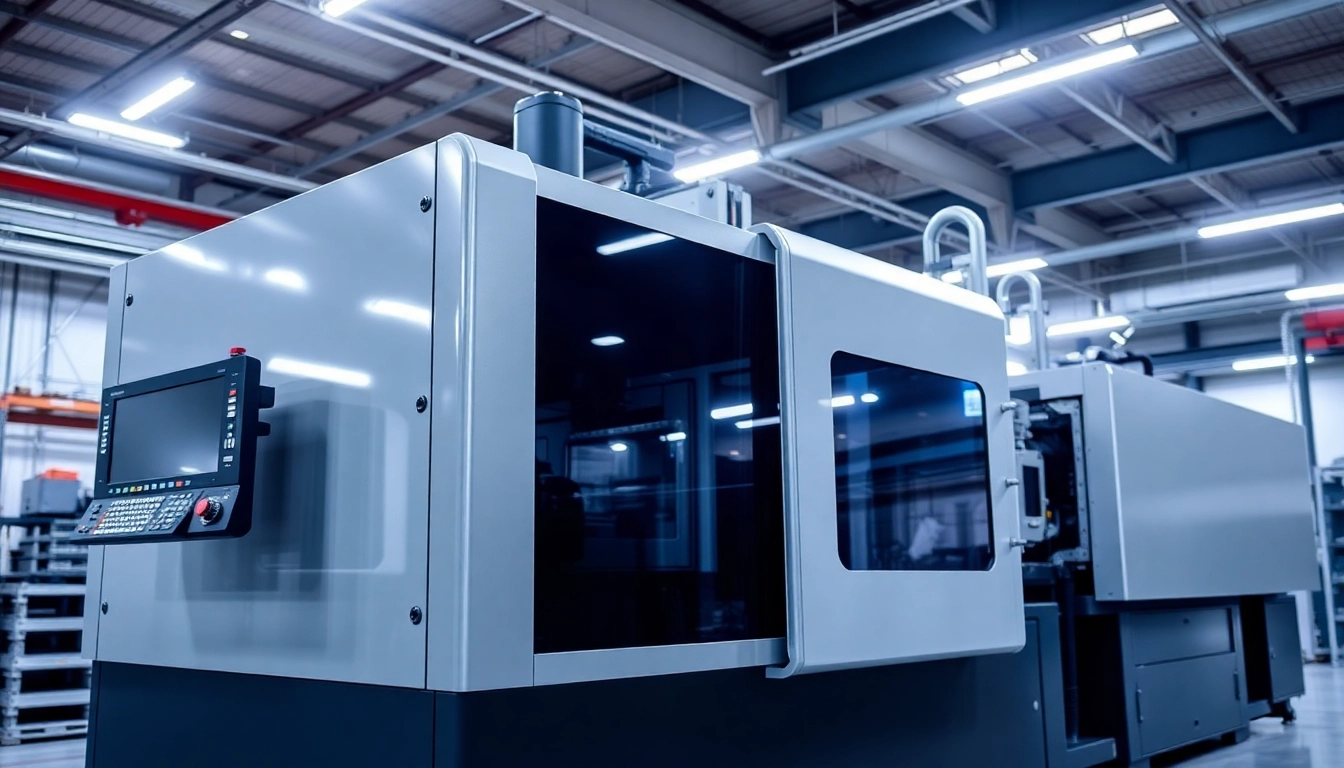

Injection molding machines are vital pieces of machinery in the industrial manufacturing process, primarily used for producing a wide variety of parts and products from materials, mainly plastics. The fundamental principle behind injection molding involves melting plastic raw materials and injecting the melted material into molds where it cools and hardens into the desired shape. This process allows for the efficient mass production of various items, from household goods to intricate automotive components.

Notably, the technology associated with injection molding machines has continually evolved, contributing to increased efficiency and versatility in manufacturing. The niche within the industry is notably supported by various machine series, including the Topstar innovation in the field. Their comprehensive range of Injection Molding Machines caters to diverse industrial needs, ensuring optimized production capabilities.

Key Components of Injection Molding Machines

Understanding the essential components of an injection molding machine is crucial to appreciating its functionality. The major components include:

– Hopper: This is where the raw material is fed into the machine. It must be carefully designed to ensure an even flow of plastic into the melting unit.

– Injection Unit: The heart of the machine, the injection unit is responsible for melting the raw material and injecting it into the mold with precision. It consists of a screw and barrel system wherein the material is heated and moved forward.

– Clamping Unit: This component holds the mold in place during the injection process. The clamping unit must generate enough force to withstand the pressure created when the liquid plastic is injected into the mold.

– Molds: Often made from steel or aluminum, molds are designed according to specific specifications to shape the injected material into the desired product. They often contain intricate features to create detailed final parts.

– Control System: Modern injection molding machines are equipped with advanced control systems that allow for precise manipulation of the injection process variables, such as temperature, pressure, and time.

Each of these components works harmoniously to create a system that can produce complex shapes with high accuracy and repeatability.

Benefits of Using Injection Molding Machines

Utilizing injection molding machines provides several advantages, especially pertinent for industries focused on production efficiency and quality. These benefits include:

– High Efficiency: Once set up, injection molding machines can produce thousands of identical products quickly, significantly reducing production time.

– Cost Effectiveness: The initial investment in molds and machinery can be high, but the long-term savings associated with mass production often outweigh these costs.

– Design Flexibility: Injection molding enables intricate design possibilities, allowing manufacturers to produce complex parts with high precision.

– Material Variety: Different plastics and materials can be employed, including thermoplastics and thermosetting polymers, making injection molding versatile for various applications.

– Reduced Waste: The precision of the injection process minimizes material waste, making this method also environmentally favorable.

These benefits make injection molding machines an indispensable aspect of modern manufacturing.

Types of Injection Molding Machines

Electric Injection Molding Machines Overview

Electric injection molding machines, such as the TEII series from Topstar, leverage advanced technology that promotes energy efficiency and precision. They utilize electric actuators for all movements, including injection, clamping, and ejection. This enables:

– Higher Precision: Electric machines are known for their accuracy in controlling the injection process, achieving tight tolerances for intricate parts.

– Energy Savings: Compared to hydraulic alternatives, electric machines consume less power, resulting in significant reductions in operational costs over time.

Moreover, these machines come equipped with top-quality components, including high-rigidity templates in their clamping units, which not only stabilize the product but also protect the mold during operation.

Servo-Driven Injection Molding Machines Explained

The TMII series from Topstar represents an innovative approach to servo-driven technology in injection molding. These machines are designed to:

– Integrate the Injection Molding Process: With a unified control interface, multiple devices work together seamlessly, significantly improving operational efficiency.

– Automatic Compensation: Advanced features allow for automatic adjustments based on real-time feedback during the injection cycle, enhancing accuracy.

– Precision with Automation: The integration with injection molding robots allows for precise part handling, ensuring meticulous production cycles resulting in fewer defects.

By emphasizing automation, these machines can produce tightly defined plastic parts with complex geometries and enhanced aesthetics, catering to sophisticated market demands.

Direct Press Type Injection Molding Machines Features

Direct press type injection molding machines, represented by the TH series of Topstar, serve as flexible solutions for larger scale manufacturing needs. They encompass:

– Two-Plate Clamping Mechanism: This design ensures a robust mold opening stroke, making the machines ideal for large-format and deep-cavity products.

– Standardized Platforms: Both small, medium, and large machines feature shared platforms that can be integrated into various production lines for cost-efficient upgrades.

With a simple yet effective design, the TH series addresses the needs of automatic part-picking applications, enhancing efficiency further in mass production scenarios.

Innovations in Injection Molding Technology

The Role of Automation in Injection Molding

The ongoing integration of automation within injection molding processes cannot be overstated. Automated systems revolutionize production by introducing features like:

– Real-Time Monitoring: Advanced sensors and software solutions now enable manufacturers to monitor the production processes continuously, ensuring early detection of any issues.

– Robot Integration: As highlighted with Topstar’s TMII series, collaboration with robotic technology allows for better-speeded assembly and handling, improving overall operational speed.

Automation equips manufacturers with the ability to scale production while maintaining or even improving quality control, creating a more robust manufacturing ecosystem.

Energy Efficiency in Modern Injection Molding Machines

In an age where sustainability is paramount, energy efficiency in manufacturing processes has gained significant importance.

– Reduced Power Consumption: Many modern machines are designed to minimize energy usage while maximizing output. The electric and servo-driven machines inherently consume less power compared to conventional hydraulic models.

– Energy Recovery Mechanisms: New technologies involve energy recovery systems that can recapture and reuse energy spent during various machine operations.

These advances not only contribute to lower operational costs but also reduce the overall carbon footprint of manufacturing sectors.

Material Advancements for Injection Molding

The injection molding landscape has evolved alongside developments in materials science, allowing for more innovative and efficient production capabilities.

– High-Performance Polymers: The introduction of advanced polymers has enabled the production of lighter, stronger, and more durable plastic components that withstand extreme conditions.

– Recyclable Materials: As environmental awareness grows, the use of reclaimed plastics and bio-based materials is becoming more prominent in the industry, paving the way for sustainable production practices.

This continuous evolution allows injection molding processes to be adapted for various applications, meeting both functional and ecological standards.

Choosing the Right Injection Molding Machine for Your Needs

Factors to Consider When Buying an Injection Molding Machine

When investing in an injection molding machine, several factors should guide your decision-making process, including:

– Production Volume Requirements: Assessing the volume of parts needed will determine the type of machine most suited for those needs, whether high-speed electric machines for large output or smaller, specialized machines for niche markets.

– Material Selection: Based on the desired properties of the final product, you may need machines that accommodate specific materials alongside their processing characteristics.

– Budget Constraints: Establishing a budget upfront will guide the selection process and assist in evaluating both upfront costs and long-term savings associated with operational efficiency.

Taking the time to evaluate these factors ensures the selected injection molding machine aligns with production goals and operational efficiencies.

Comparing Models: TEII vs. TMII vs. TH Series

Choosing between the TEII, TMII, and TH series from Topstar will depend on your specific manufacturing needs. Below are factors to consider:

– TEII Series: Best suited for applications that require high precision and energy efficiency. Ideal for manufacturers focusing on reduced operational costs with consistent quality.

– TMII Series: The go-to for those looking to leverage cutting-edge servo technology alongside automation capabilities. Optimal for producing complex parts needing fine details and high production speeds.

– TH Series: Recommended for those focused on large formats and deep-cavity products, providing robust operation under varied production demands.

Evaluating your production needs will assist in determining which series will best serve your production line.

Customization Options for Injection Molding Machines

Customization options are crucial with injection molding machines, allowing manufacturers to cater specifically to their unique production demands. These may include:

– Configurable Specifications: The ability to tailor machine features like clamping force, injection speed, and cooling time according to the required product specifications.

– Mold Design Capabilities: Partnering with machine manufacturers to develop molds that can enhance production efficiency and accommodate specific part features.

– Peripheral Interfaces: Integrating additional hardware or software systems that seamlessly connect with the injection molding machine, enhancing performance and control.

Customization can significantly enhance manufacturing efficiency, ultimately leading to improved productivity and product quality.

Maintenance and Troubleshooting for Injection Molding Machines

Best Practices for Injection Molding Machine Maintenance

Proper maintenance is essential for ensuring longevity and consistent performance in injection molding machines. Key practices include:

– Regular Inspections: Frequent assessments of machine components for wear and tear will help detect potential issues before they escalate.

– Lubrication: Keeping mechanical parts adequately lubricated reduces friction and wear, extending the machine’s lifespan and maintaining operational efficiency.

– Training for Operators: Ensuring personnel are well-trained in operating and maintaining machines contributes directly to minimized downtime and maximized productivity.

Following these best practices ensures smooth operation and helps avoid costly production interruptions.

Common Issues and Solutions in Injection Molding

Injecting efficiency into your production process requires an understanding of common issues faced in operation and their corresponding solutions:

– Molding Defects: Common defects such as warping, sink marks, or short shots can often be traced back to improper temperature settings or inadequate mold design. Fine-tuning these parameters can resolve issues promptly.

– Material Flow Problems: Solutions like adjusting injection speed or temperature settings can alleviate blockages while also ensuring that the material flows consistently into the mold cavity.

– Mechanical Failures: Issues such as hydraulic leaks or mechanical wear can significantly impact production. Scheduled maintenance and immediate responses to abnormal machine behavior can prevent these challenges.

Addressing these issues promptly can save time and expense, maintaining optimal production quality standards.

When to Consult a Professional for Injection Molding Machines

While many issues can be resolved through in-house troubleshooting, recognizing when to consult a professional is essential. Situations that warrant professional intervention include:

– Complex Mechanical Failures: When a machine experiences recurring issues that cannot be addressed through routine maintenance, bringing in an expert can provide deeper insights and solutions.

– Upgrading Systems: If you are considering major upgrades or automation enhancements, consulting a specialist ensures a smooth integration process that leverages the latest technologies effectively.

– Mold Design Changes: Significant modifications in mold design may require professional input to ensure they align with the machine’s capabilities and maintain production efficiency.

Utilizing expert assistance appropriately can optimize your injection molding operations, aiding in leaner, more effective manufacturing strategies.